steigw

Member

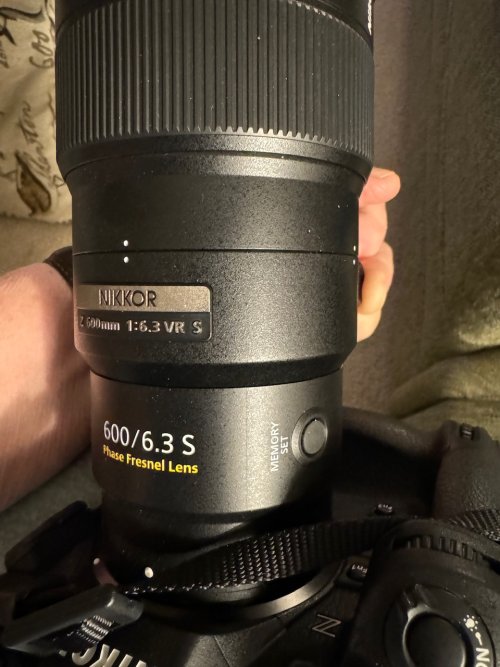

Just got my z600pf f6.3 and noticed there is a seam on the top left and right of the lens. The seam on the right is particularly noticeable. Think this could result in problems in the future where the material pulls apart?

I’m contemplating returning it and requesting a new copy. Purchased direct from Nikon USA.

Has anyone seen this sort of seam before? Think it would be considered a construction defect?

I’m contemplating returning it and requesting a new copy. Purchased direct from Nikon USA.

Has anyone seen this sort of seam before? Think it would be considered a construction defect?